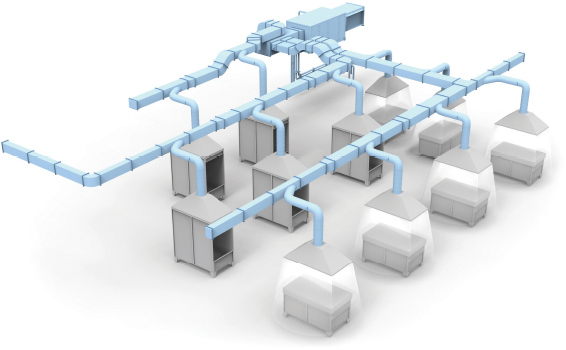

Technology that prevents diffusion by removing pollution generated at a certain position

It is a technology that prevents the discharge from entering the workspace by setting the capture and removal areas for the pollutants that generate the discharge. It considers various variables in the workspace and combines a single or two or more modules to design the most suitable for the workspace.

Process

-

Stage 1

Generation Amount Calculation

Identify the physical and chemical characteristics of gas emissions and calculate the amount of generation

-

Stage 2

Airflow Determination

Design hoods and determine required airflow to set target contamination capture and removal areas

-

Stage 3

Identification of Character-istics and Arrangement

Identify the characteristics and workspace layout to which you want to introduce the system

-

Stage 4

Spatial Identification

Identify the space to install the rear blower (or air purifier)

-

Stage 5

Schematization after Duct Identification

Identify the path of the air transfer duct and schematization

-

Stage 6

DSBM Progress

Determine the duct size, sha- pe, length, number of elbows, etc. with balanced design (DSBM) for each air transport duct section

-

Stage 7

Determination of Pressure and Power Values

Determine the pressure value and blower motor power required for the entire system

-

Stage 8

Drawing Creation

Create design drawings based on the determined data

Type

Mobile

Fans and exhausts can be moved and applied almost anywhere

ex) Small space or small amount of pollutant emissions

Fixed

Space where the location of the pollutants is fixed and the gas discharge conditions are constant

ex) robot welding, chemical reactors, raw material mixers, laboratories, etc.

Variable

When the location of the pollutants changes and the duct needs to be moved or changed

ex) manual welding, grinding, solder gas discharge, etc.

Applicable Fields

- Robot Welding Process

- Powder Coating

- Kitchen

- Process Plant

- Shooting Range

- Laboratory

- Etc.