Cooking room ventilation system

Implement air supply and exhaust volume by customized ventilation design system for each school

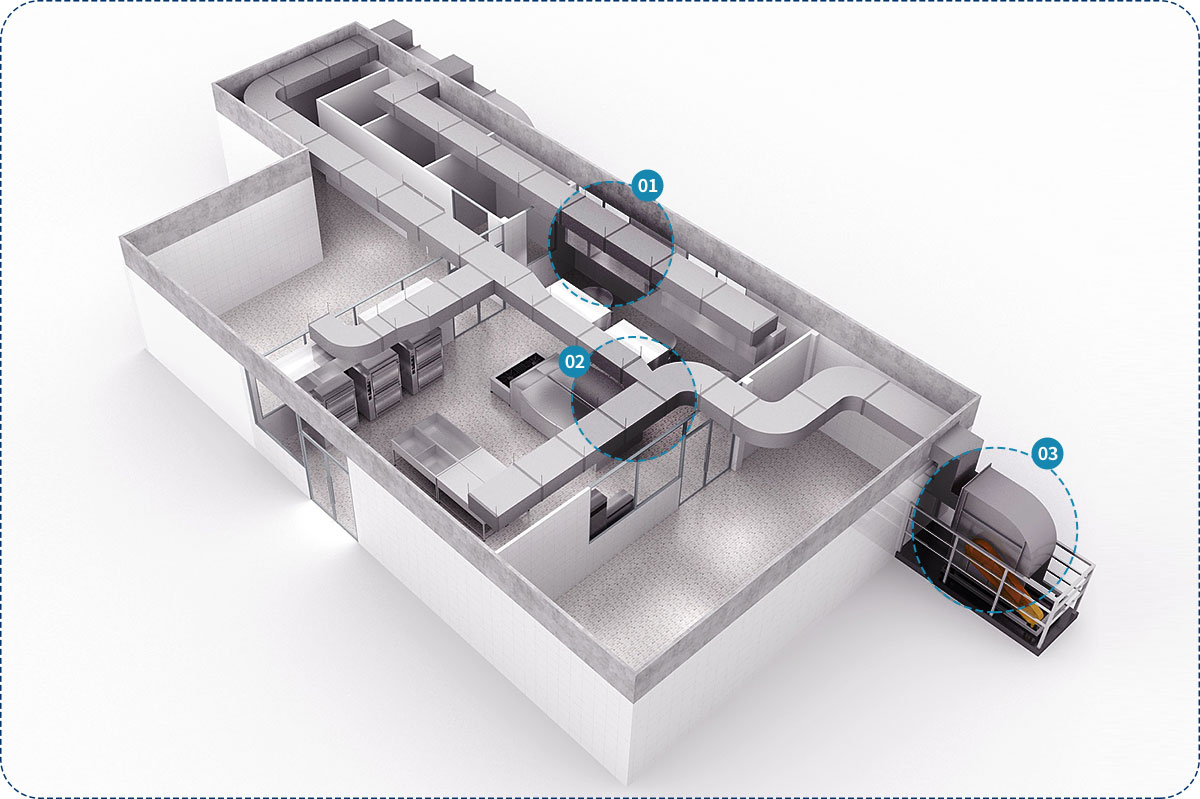

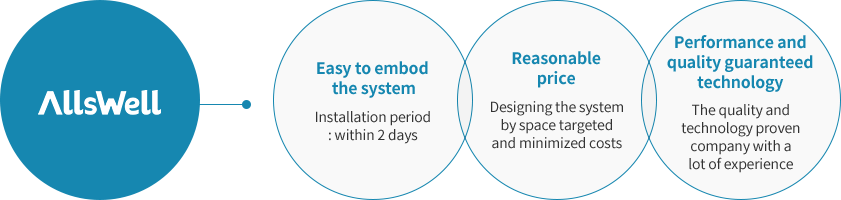

OPTIMIZED AND CUSTOMIZED COOKING ROOM VENTILATION SYSTEMCooking room ventilation system from ALLSWELL improves the environment of cooking and cafeteria area by implementation of optimized and customized ventilation system

CORE TECHNOLOGY OF COOKING ROOM VENTILATION SYSTEM

CORE TECHNOLOGY OF COOKING ROOM VENTILATION SYSTEM

-

Implement air supply and exhaust volume by customized ventilation design system for each school

Implement air supply and exhaust volume by customized ventilation design system for each school

Optimized air volume & static pressure for target space based on USA standard(ACGIH and ASHARE)

-

Hood air volume distribution design

Hood air volume distribution design

Conduct DSBM(Duct Segment Balance Method)

& CFD simulation

To improve existing facility capabilities

(Fan capability up : no duct construction)

-

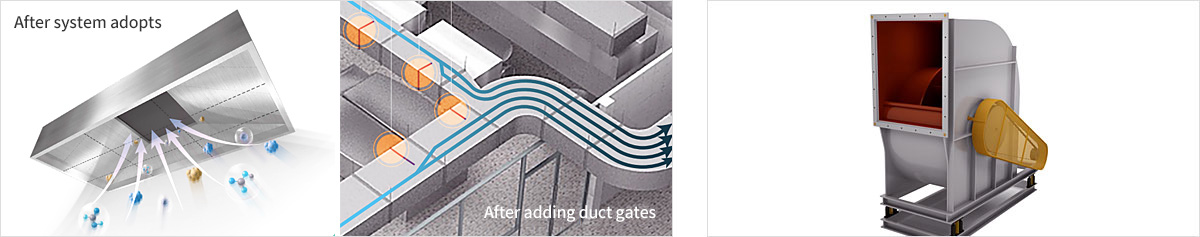

01. Fan capability up by no internal duct system changes

Total power capability up by motor, pulley and belt replacement

-

02. Improving air distribution of each hood at cooking area

Adjustment of internal damper and adding duct gates

Adding high efficiency fan

(Optimized and customized essential air volume calculation)

-

03. Designing the most optimized ventilation system by adding high efficiency fan

Optimized air volume & static pressure for target space

-

Performance guarantees by quantified figures

Performance guarantees by quantified figures

on the documentary"USA ACGIH, USA ASHARE,

Following Rules of the domestic school health,

Guidelines of ventilation system installation in school cooking room,

Technical guidelines for ventilation of group meal service facilities in Korea" -

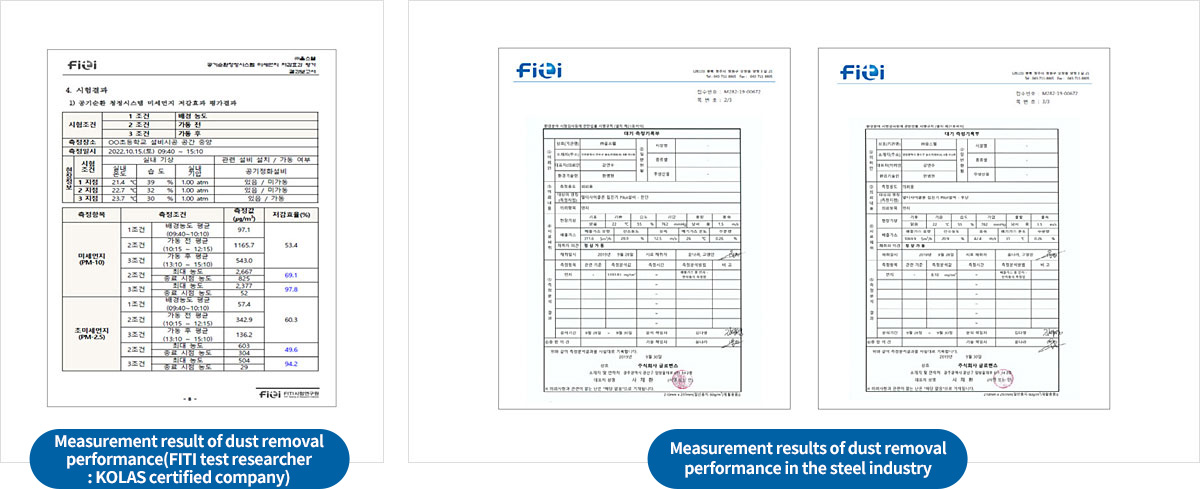

Performance and quality

Performance and quality

guaranteed technology"Installation air circulation and cleaning system in Incheon,

Technology verified through performance measurements

Government and local government collaboration projects

Recognized as the best air technology company in the industrial field"

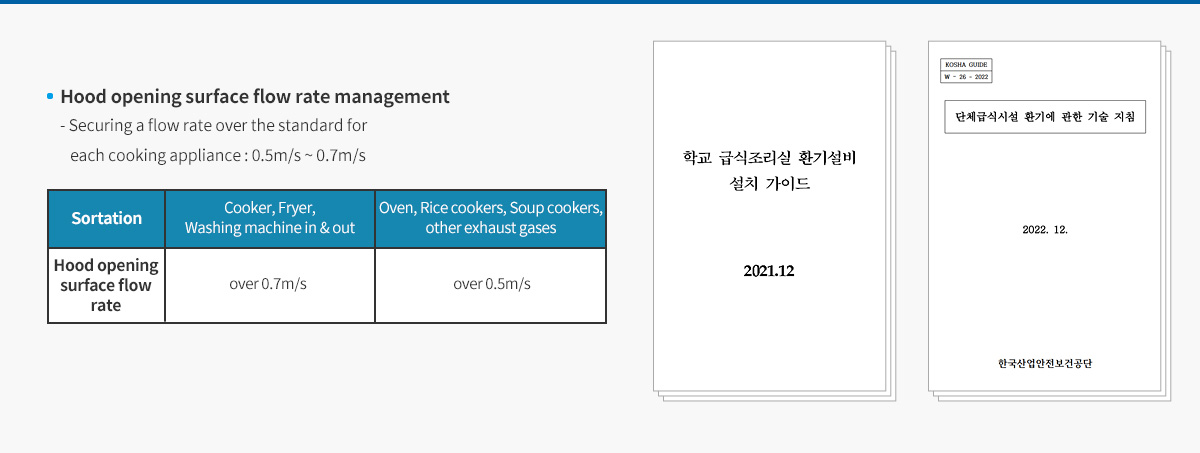

STANDARD OF COOKING ROOM VENTILATION SYSTEM DESIGN

STANDARD OF COOKING ROOM VENTILATION SYSTEM DESIGN

Guidelines of ventilation system installation in school cooking room

(Employment and labor department distributed Dec 2021)

Technical guidelines for ventilation of group meal service facilities

(Korea Occupational Safety and Health Agency distributed Dec 2022)

by implementation of optimized and customized ventilation system

Cooking fume / CO2/ CO/ VOC Hazard Chemical substances / Reducing the concentration of fine dust

/ Prevention of inflow of fine dust from outside

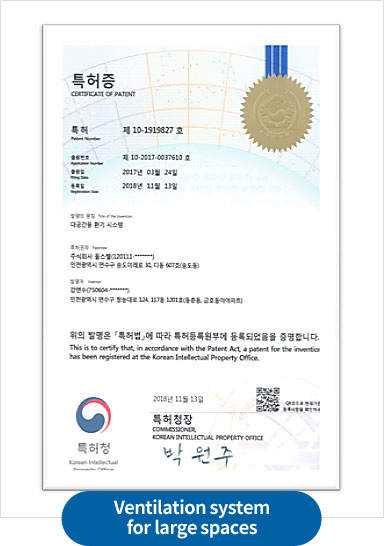

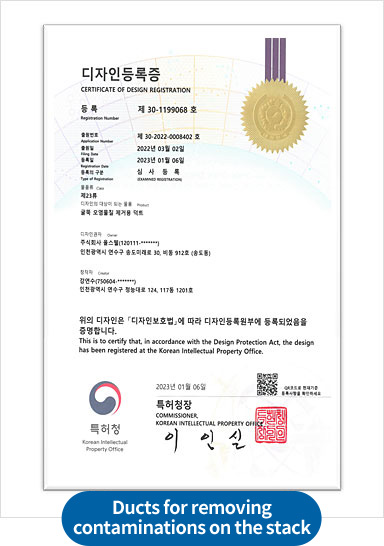

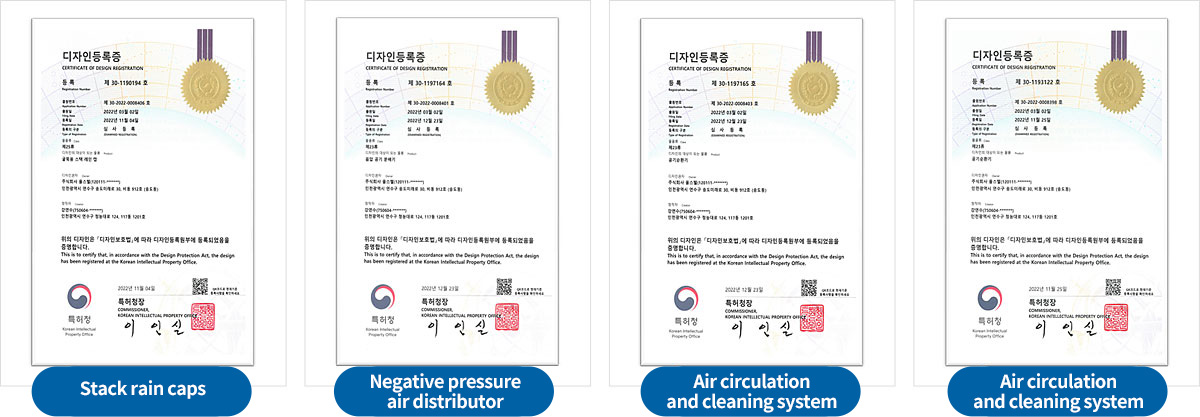

Patent technology for cooking room ventilation system

SIMILAR REFERENCES OF VENTILATION AND DUST COLLECTION SYSTEM

SIMILAR REFERENCES OF VENTILATION AND DUST COLLECTION SYSTEM

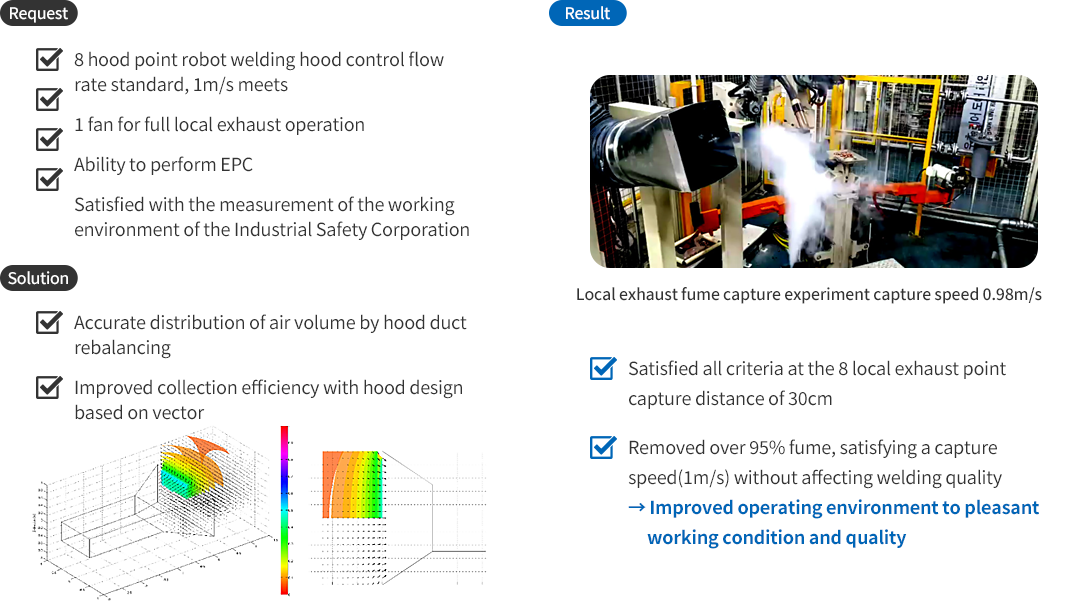

- Air volume distribution and design by hood flow rate management for 8 hood points

- Satisfied standard of welding fume hood flow rate and licensing(working condition measurement) approved by duct rebalancing

- Air flow rate management of each hood for target space

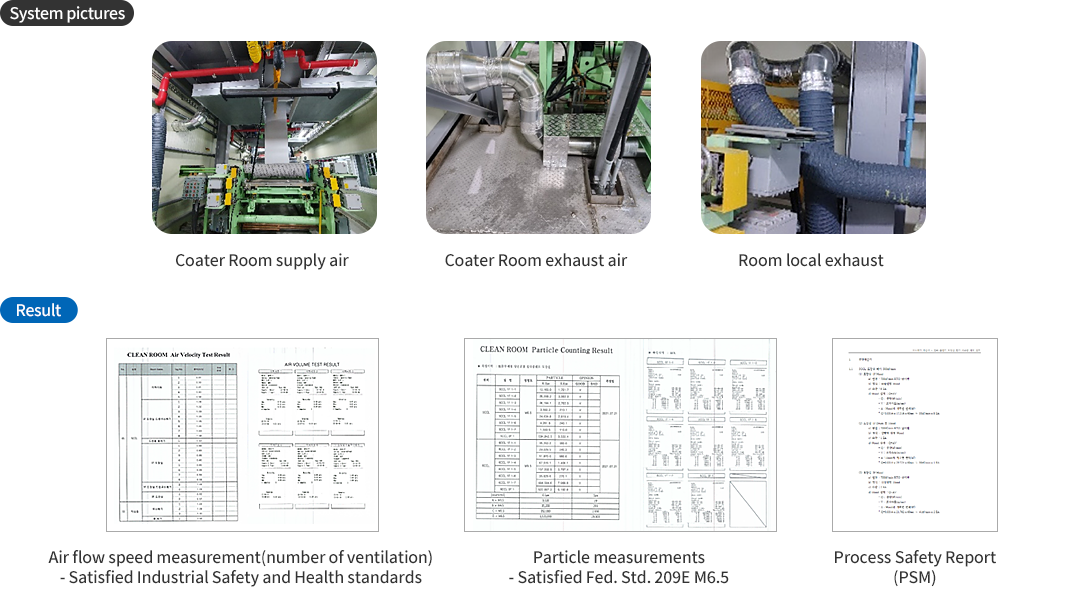

- "A system to prevent the spread of hazard substances(Thinner series) and the inflow of external dust in the color steel painting room Design/construction and licensing(PSM) approved"

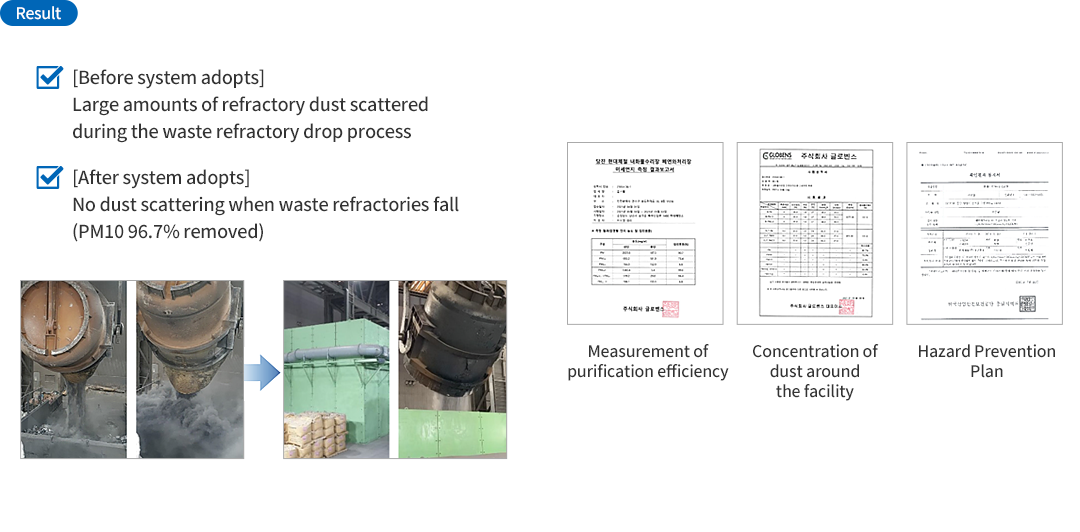

- Design/contruction and licensing approved of a system to prevent the spread of large amounts of dust at waste refractory treatment

- Achieved 96.7% scattering dust reduction rate based on PM10

Main customers

TECHNICAL SUPERIORITY PROVEN

TECHNICAL SUPERIORITY PROVEN

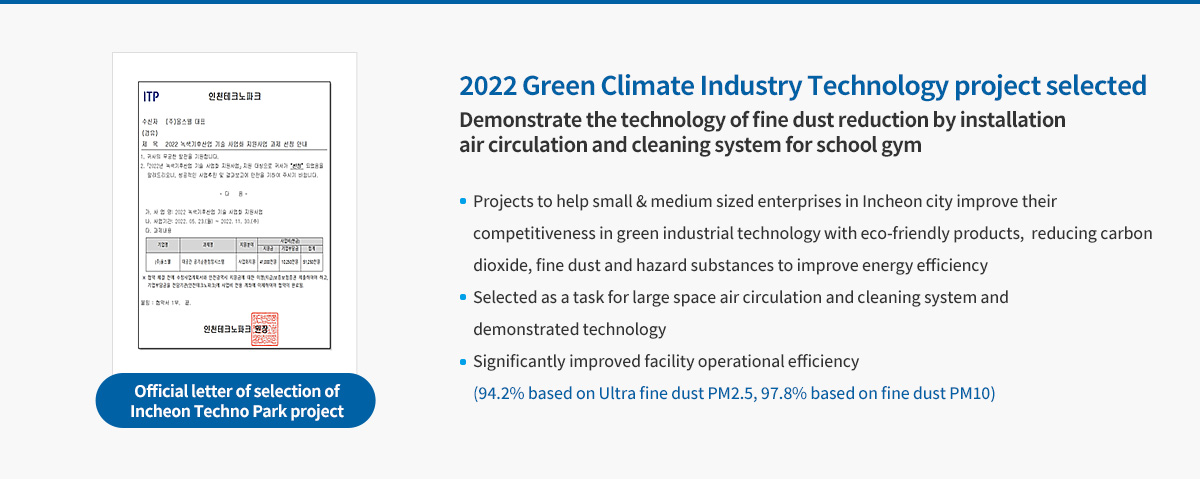

Green Climate Industry Technology project selected, Companies with the best technology certified as small

& medium sized enterprises in Incheon city

MEDIA REPORT

MEDIA REPORT