Productivity improvement & energy saving system

Based on industrial air technology (IAT), the gas flow of the existing ventilation system is analyzed quantitatively, and ducts and blowers are redesigned accordingly to increase efficiency and reduce power cost.

Existing Design

-

1Calculation of airflow without considering site conditions and characteristics of pollutants

-

2Waste of energy and cost due to excessive design of airflow

-

3Installation and addition of duct without considering energy balance

-

4Performance deterioration due to collapse of energy balance by damper adjustment

Optimization Design

-

1Calculation of the optimal airflow considering the site temperature, humidity, evaporation rate of pollutants, and vapor pressure

-

2Energy balance adjustment of duct and branch pipe using DSBM of ALLSWELL Co., Ltd.

-

3Minimal damper use with optimal airflow and energy balance design

Capacity of the blower or the number of units can be reduced

AT-based diagnosis and design can reduce power cost

Payback period (ROI) of 6 months is guaranteed

Payback period (ROI) of 6 months is guaranteed

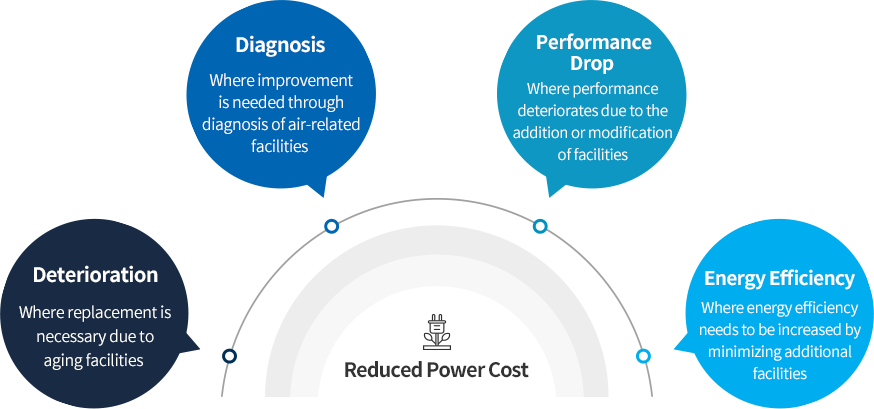

Scope of Application

전력비 절감

-

Deterioration

Where replacement is necessary due to aging facilities

-

Diagnosis

Where improvement is needed through diagnosis of air-related facilities

-

Performance Drop

Where performance deteriorates due to the addition or modification of facilities

-

Energy Efficiency

Where energy efficiency needs to be increased by minimizing additional facilities